Introduction

Effective troubleshooting is essential because the M32T Pro160 represents one of the more complex electronic devices available. The M32T Pro160 functions regularly in automotive and industrial electronics applications due to its precise approach and dependable performance. Complicated machinery tends to experience operational problems eventually. One such issue that users have reported is the phenomenon where the M32T Pro160 negative on the capacitor starts smoking. It is a concerning situation that can lead to potential damage to the device and even pose safety risks if not addressed promptly.

People who operate or maintain the M32T Pro160 must comprehend all aspects of this phenomenon and its corresponding solutions. We will examine the possible sources behind this problem as well as what harm the negative charge does to capacitor starters and provide diagnostic and resolution measures for fixing the issue.

Understanding the M32T Pro160 and Its Components

The automotive diagnostic tool M32T Pro160 operates as a high-end device that connects to vehicles combined with industrial equipment. The diagnostic tool presents refined monitoring capacities for multiple automobile brands along with capabilities like ECU reprogramming, key creation functionalities, and equipment assessment. Multiple capacitors and resistors with other electrical components allow this device to execute its functions reliably.

The M32T Pro160 uses its capacitors to manage and refine electrical voltage to achieve smooth tool operation. A smoking negative capacitor finds its origins in broken componentry, flawed power supply components, or short circuits that overtax the total current flow. Fundamental knowledge about capacitors enables people to identify and solve electronics problems.

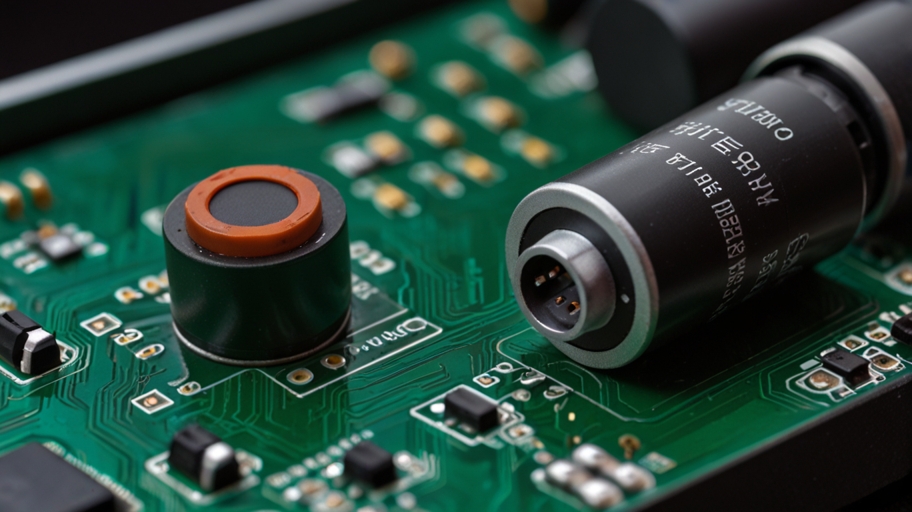

The Role of Capacitors in Electronics

All electronic circuits require capacitors, which play a crucial functional role. They function as electrochemical tanks to save and distribute electrical energy, which preserves both voltage levels and current stability. Electrical components rely on capacitors to function in energy storage applications, timing applications, and signal processing operations. The M32T Pro160 tool uses capacitors to control power inputs, which direct electricity throughout each component area.

Connection of the cathode segment occurs at the negative side of polarized capacitors. The structure of polarized capacitors is created to accept direct current (DC) only in one specific direction. A burning negative capacitor terminal often signals capacitor damage from either high voltage or wrong polarity application or other electrical faults, leading to the destruction of the device.

Identifying the Symptoms of Capacitor Failure

Before we dive into troubleshooting, it is important to recognize the signs of capacitor failure, especially when the negative on the capacitor starts smoking. Here are some key symptoms that may indicate a capacitor is malfunctioning:

- Visible Smoke or Fumes: If the negative side of the capacitor starts smoking, this is often a sign that the capacitor is overheating and may have ruptured or leaked.

- Decreased Performance: The M32T Pro160 might exhibit poor performance or fail to power on properly if the capacitor is damaged.

- Power Surges or Flickering: Capacitors are responsible for smoothing power delivery. If they fail, you may notice power surges, flickering, or instability in the tool.

- Burnt or Discolored Capacitors: A physical inspection of the capacitor may reveal signs of burning, discoloration, or bulging, which are clear indicators that the component has failed.

- Noisy or Distorted Output: In some cases, the malfunctioning capacitor can cause noise or distortion in the output signal of the device.

Recognizing these symptoms can help prevent further damage to the M32T Pro160 and help you take corrective actions before the issue worsens.

Potential Causes of the Negative on the Capacitor Starting to Smoke

Several conditions can result in M32T Pro160 negatives, which cause capacitors to start emitting smoke. The identification of possible causes helps professionals to fix and solve this problem effectively.

1. Overvoltage or Incorrect Voltage Supply

High voltage is among the leading causes of capacitors becoming hot enough to produce smoke. The M32T Pro160 will experience a premature failure of its capacitor when voltage levels higher than its design specifications from its power source are given. When the setup process delivers an improper voltage to the system or power issues occur, the capacitor may start to smoke.

When subjected to voltages beyond their rated capacity, capacitors experience overheating followed by leakage and, ultimately, driver rupture. Smoking typically emerges from the negative terminal when capacitor installations fail. Regulatory inspections of power supply voltage are essential to verify that equipment receives its needed electrical input.

2. Incorrect Polarity

The wrong connection pattern of capacitor terminals is a likely reason for this situation. The proper alignment of positive and negative capacitor leads remains essential because incorrect orientation prevents reverse voltage from developing. Any mistake in the M32T Pro160 assembly or improper capacitor polarity connection can cause negative side overheating that leads to smoke production.

Bad connections of opposing polarities trigger capacitor failure through characteristic bulging and leakage and prevailing smoke. Guests should always check capacitor orientation both when installing new components and when making replacements in electronic devices to prevent reverse voltage application.

3. Short Circuit or Faulty Components

Simultaneous device short circuits trigger capacitor overheating, which results in capacitor smoking. A short circuit across the power supply or inside the M32T Pro160 circuitry will cause the capacitor to absorb excessive current, which generates heat until failure. The simultaneous power surge flowing through the capacitor creates smoking at its negative end, causing potential harm to surrounding circuit components.

Companies utilizing faulty resistors or transistors alongside diodes may permit random current flows, which can cause capacitor damage. An overheating problem could result from either a short circuit or a malfunctioning component in the power circuits.

4. Excessive Heat

Capacitors remain sensitive to temperature changes; thus, they require specific operating temperature ranges. High temperatures in the M32T Pro160 operational environment, accompanied by limited heat dissipation capacities resulting in capacitor temperatures exceeding safety limits, can lead to overheating of the component. Performance issues indicated by capacitor negative part smoke could result from extended high-temperature exposure.

Heat buildup occurs from inadequate ventilation, faulty cooling methods, or defective fan operation. The life span of capacitors depends heavily on proper maintenance combined with suitable environmental conditions to protect both the capacitor and the entire device system.

5. Manufacturing Defects

The beginning of negative smoke from the M32T Pro160 capacitor might stem from production defects among the manufactured capacitors. Product quality control problems during manufacturing steps could result in capacitor defects, even though this occurrence remains fairly uncommon. The use of faulty capacitors can result in early component failure, which creates conditions where the part overheats while leaking or rupturing.

Note that defective capacitors might result from manufacturing flaws, so contact M32T Pro160 producers to obtain a replacement unit. A component analysis reveals an intrinsic design issue rather than external reasons for failure in this situation.

Troubleshooting Steps: How to Resolve the Issue

When the M32T Pro160 negative on the capacitor starts smoking, it is important to act quickly to prevent further damage and ensure the device continues to operate correctly. Below are the essential troubleshooting steps to take when you encounter this issue:

1. Power Off the Device Immediately

You should start troubleshooting by turning off the M32T Pro160 unit and then pulling out all power connections. Running the device with a failed capacitor can trigger additional harm to internal sections, thus creating more significant repair issues.

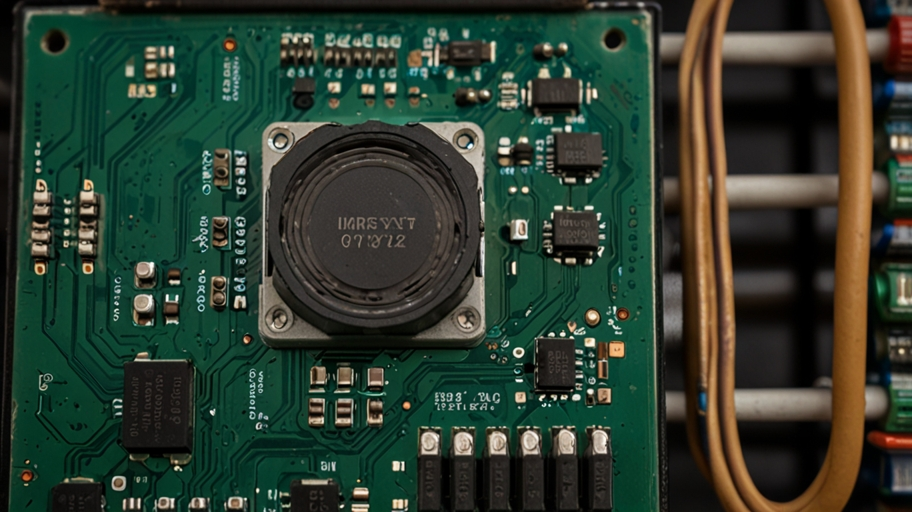

2. Inspect the Capacitor

After turning off the device, look for any cosmetic damage on the capacitor by checking for swelling or discoloration. Verify the capacitor polarization because this signals correct installation. The capacitor requires replacement if you detect any problems during your inspection.

3. Check the Power Supply

Verify that the power supply properly gives the appropriate voltage to the M32T Pro160. A multimeter checks the voltage, which you need to compare against the product specifications. You should change either your power supply or adjust its settings if the provided voltage exceeds what the device requires.

4. Test for Short Circuits

You should examine the circuit for shorting conditions through the use of a multimeter on the continuity test. The capacitor withstands excessive current via short circuits, which produces overheating and, eventually, smoking. Identifying faulty parts remains essential before capacitor replacement when short circuits exist.

5. Replace the Capacitor

If the capacitor has been damaged beyond repair, it will need to be replaced. Ensure that the replacement capacitor matches the specifications of the original component, including the voltage rating and capacitance. Installing the correct capacitor is crucial to restoring the proper functioning of the M32T Pro160.

6. Reassemble and Test the Device

After replacing the damaged capacitor and verifying that all components are functioning correctly, reassemble the M32T Pro160 and perform a test. Ensure that the device powers on without any issues and that the capacitor does not overheat or smoke during operation.

Preventing Future Issues

The correct maintenance protocol and responsible device treatment remain essential aspects. Examine your device periodically to detect signs of deterioration or damage, which prioritize the power supply and capacitor portions. The system should stay away from operating in both hot or cold extreme weather conditions alongside environments that lack proper ventilation. Moreover, you must install your components properly and use the correct power source at all times.